improved

Inventory Levels Audit

A new tab has been added to the Inventory View --> Warehouse Stock tab called “Inventory Levels Audit”.

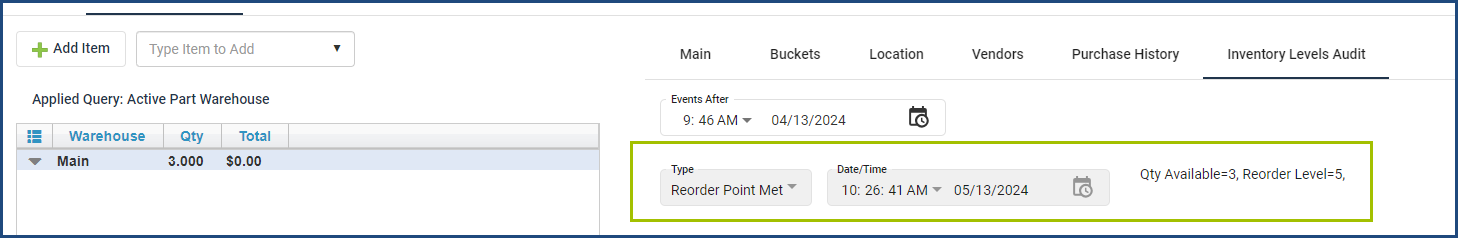

This tab allows you to track stock levels in relation to the reorder points listed on the Inventory record. You’ll be able to see what date/time an item went at or below your set Reorder Point and what the Reorder Point was at the time of the audit.

How to use:

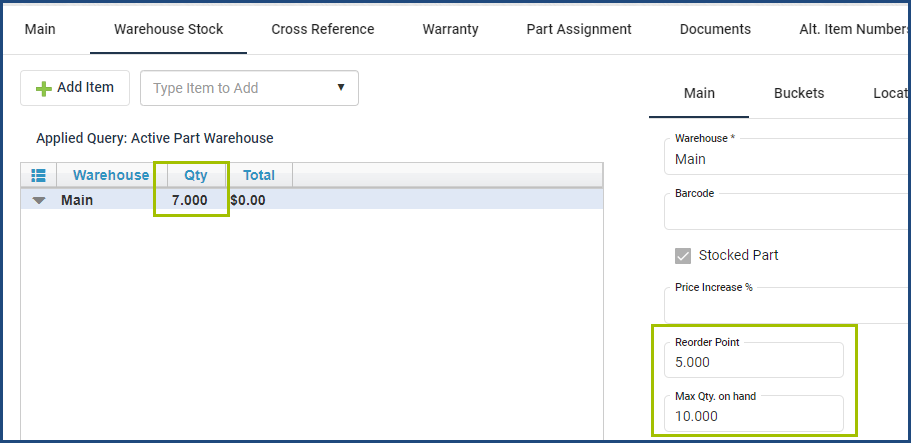

You must have your Reorder Points and Max Qty on Hand fields filled out on the Inventory record. When an item’s quantity hits or dips below the reorder point, an audit point will appear on that tab that tells you the date/time the item met or went below the reorder point, what the qty was, and what the reorder point is. Once it hits below the reorder point without being restocked, it will not continue to add records on this tab; it only will take the first time it went below the point.

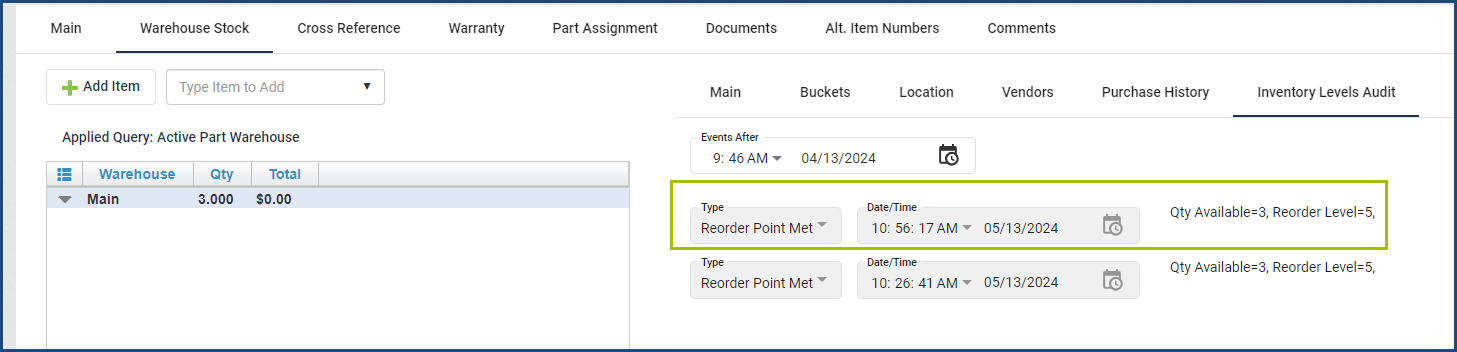

After an additional quantity is added, another point will be added if the item goes below the reorder point.

Example:

Part ABC has a Reorder Point of 5 and a Max Quantity of 10. There are currently 7 in stock.

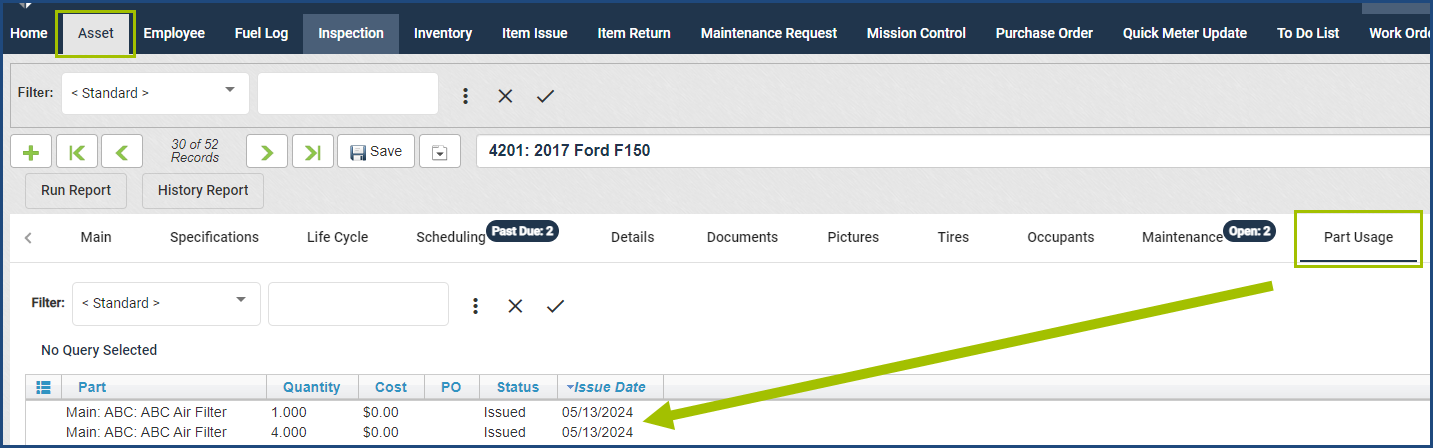

- 4 were used on a Work Order, which brought the available quantity to 3. An audit point will appear on the tab, with a current Qty Available of 3 and Reorder Point of 5.

- Another Work Order used 1 of these items, which brings the Quantity on Hand down to 2. There will notbe an additional audit listed, because the quantity already hit below the Reorder Point.

- A Purchase Order was then received in for this part, and the quantity went back up to 10 (the Max Qty).

- Another Work Order was done and used 7 of this part, which brought the quantity on hand to 3. An Audit point willappear on the tab, because it’s the first time it went below the reorder point after more quantity was added.

Please see the Inventory section of the software User Guide for more information if needed.